In the world of electronics, simplicity, reliability, and cost-efficiency are often critical factors. Single-Sided PCB technology addresses these requirements by offering printed circuit boards with a single conductive layer, making them ideal for a wide range of basic electronic devices. These boards are commonly used in consumer electronics, household appliances, and low-complexity industrial applications.

What Is a Single-Sided PCB?

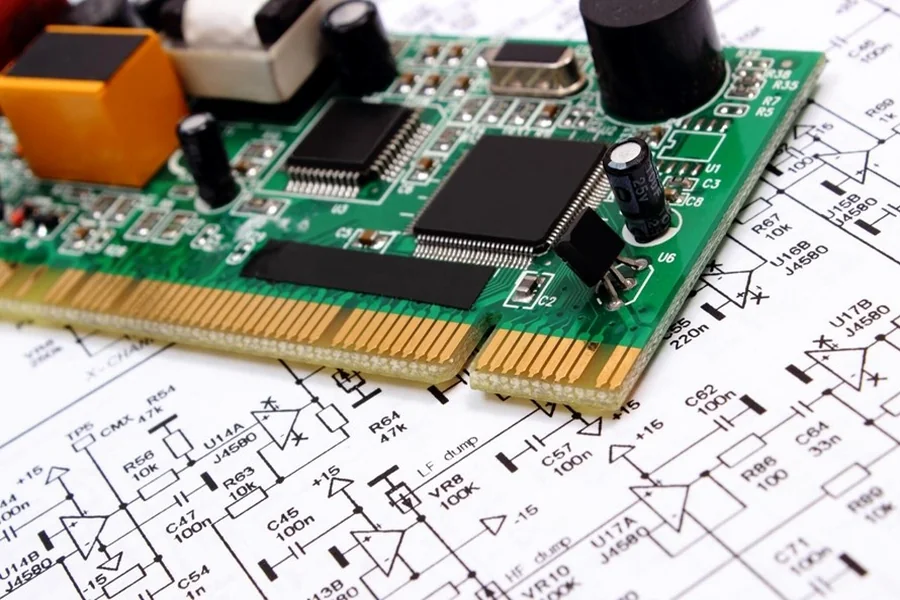

A Single-Sided PCB consists of a single layer of conductive copper on one side of an insulating substrate. Components are mounted on one side of the board, while the copper traces form the electrical connections. This straightforward design makes single-sided PCBs easier and faster to manufacture compared to multilayer or double-sided boards.

The simplicity of the design allows for cost-effective production, especially for low-volume applications. Despite their simplicity, single-sided PCBs can reliably support circuits with low component density and moderate electrical performance requirements.

Advantages of Single-Sided PCB

One of the primary benefits of a Single-Sided PCB is affordability. The manufacturing process is less complex, requires fewer materials, and involves minimal assembly steps, reducing both production time and costs.

Single-sided PCBs are also easy to design and modify, making them suitable for rapid prototyping, educational purposes, and straightforward electronic products. The reduced complexity ensures lower chances of manufacturing defects, improving overall reliability.

These boards are also durable under normal operating conditions and can handle moderate heat and electrical load, making them suitable for various consumer and industrial applications. Their simplicity also allows for easier troubleshooting and repair when needed.

Applications of Single-Sided PCB

Single-Sided PCB technology is widely used in applications where complex circuit design is not required. Consumer electronics such as calculators, remote controls, and radios often employ single-sided PCBs due to their low cost and sufficient performance.

Household appliances, including washing machines, microwave ovens, and LED lighting systems, also benefit from single-sided boards, as they provide reliable operation at minimal expense. Educational kits and DIY electronics projects frequently use single-sided PCBs to teach circuit design principles, offering an accessible and affordable solution for learners.

Industrial applications such as control panels, low-power sensors, and simple automation circuits also utilize single-sided PCBs, providing a cost-effective and reliable option for basic electronic control tasks.

Manufacturing Considerations

Manufacturing a Single-Sided PCB involves applying a single copper layer onto a dielectric substrate, followed by etching to create the desired circuit pattern. Components are then mounted and soldered on the same side. Surface finishes such as HASL, ENIG, or immersion silver are applied depending on soldering requirements and long-term durability.

Quality control during production ensures that all traces are correctly formed, solder joints are reliable, and the board meets electrical specifications. This ensures consistent performance and reliability, even for simple designs.

Choosing a Trusted Supplier

Partnering with a reliable Single-Sided PCB supplier ensures access to high-quality, cost-effective boards. A reputable supplier provides precise fabrication, strict quality control, and customization options to meet various application needs. By working with a trusted Single-Sided PCB supplier, businesses can achieve reliable, affordable, and efficient circuit boards for a wide range of electronic products.